Finally, the furniture sector, bamboo, rattan, cane, and also wicker products going through a huge issue: Decrease of labor skills. This is a global issue, and not just one of local scope, as these industries are a critical enabler of production, economic growth, and sustainability for companies involved in these sectors. In this blog, we will discuss the multiple facets of labor skill shortage in this niche market, as well as their causes, implications and possible solutions.

Understanding Labor Skill Shortages

Lack of ability to provide active labor force to demand. This shortage is especially acute in the furniture manufacturing industry and is driven by a variety of reasons:

- Aging Workforce: There is an aging workforce in the furniture industry; countless skilled and talented workers are reaching retirement age, but there are not enough younger workers entering the field to replace them. This demographic transition leaves a major talent gap.

- Declining Interest From Younger Generations: There is a rising trend of younger generations seeking careers beyond manufacturing. Most prefer high-tech or service sector jobs; the ancient crafts of furniture making and the like are on the wane.

- Economic Aspects: Economic downturns or upturns can affect hiring trends. In downturns, companies might lay off workers or postpone hiring new employees, worsening skill shortages when demand picks up again.

- Regional Differences: Some regions may face more severe skill shortages than others due to local economic conditions or availability of educational pathways towards vocational training.

- Technological Progress: Due to the increasing prevalence of automation and advanced manufacturing technologies, there is a requirement for employees to be not only proficient in traditional practices, but also skilled in operating new technology.

How Shortages of Skilled Labor Affect Sectors?

The consequences of shortages of labor skills are extensive:

- Higher Production Costs: When demand for skilled labor outstrips supply, wages normally increase. This would naturally increase production costs for manufacturers, likely showing up on the price tags of consumers as well.

- Production Delays: Higher-skilled workers are often harder to recruit, resulting in longer production times and an inability to meet existing deadlines, compromising customer satisfaction and business reputation.

- Decline of Innovation: High-skilled laborers tend to have creativity and innovation in their work. A shortage can suffocate new concepts and refinements in product design and manufacturing techniques.

- Implication on Economic Growth: As the furniture industry creates significant economic growth in many economies. This growth potential will be stifled by labor shortages within the sector, as well as related industries (retail and logistics).

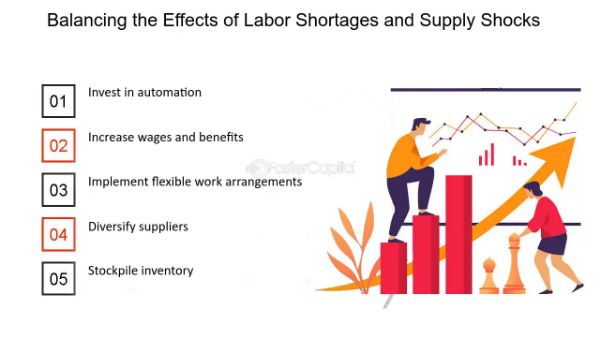

Ways to Mitigate Skill Shortages in the Labor Market

Here are several approaches that may help address labor skill shortages:

1. Financial investment in training and development

Manufacturers must invest in training programs that will prepare new workers with the skills they need to get to work. This includes:

a. Not specialized: probably some easy way to bridge the gap between education and practical work experience instrumental end-to-end

b. Collaboration with Educational Institutions: Partner with technical schools and community colleges to develop customized programs that meet the industry needs.

c. Re-skilling: Training existing employees to perform new tasks is crucial for up-skilling and keeping them motivated.

2. How to Build a Good Working Environment?

Supportive workplace culture is conducive to the retention of skilled workers:

a. Attractive Salaries: High salaries play an essential role in attracting top talent.

b. Development Of Pathway For Career Growth: Providing proper pathways of career growth helps in retaining the employees for a long.

c. Recognition Programs: Creating rewards for people who reach certain levels of achievement.

3. Leveraging Technology

Accounting technology can reduce some dependence on manual work:

a. Using Automation: Automated systems increase productivity as skilled laborers are free to handle difficult tasks.

b. And the building, so to speak, the digital work training platforms: By working with online learning platforms, companies can shareworkplace learning easily and quickly to its employees.

4. Community Engagement

There are several ways to engage with local communities that can help spark an interest in manufacturing careers:

a. Outreach: Programs that target schools and community organizations that highlight careers in furniture will help.

b. Showcasing Career Opportunities: Highlighting success stories from within the industry can inspire younger generations to consider these career paths.

5. Addressing Immigration Policies

Many industries rely on immigrant labor to fill skill gaps:

a. Advocating for Fair Immigration Policies: Engaging with policymakers to create favorable immigration policies can help attract skilled workers from abroad.

b. Support Networks for Immigrants: Establishing support systems for immigrant workers can aid their integration into the workforce.

Conclusion

Labor skill shortages pose significant challenges for the bamboo, rattan, cane, and wicker furniture industry. By understanding the underlying causes of these shortages and implementing strategic solutions—such as investing in training programs, creating positive work environments, leveraging technology, engaging communities, and addressing immigration policies—industry stakeholders can work towards building a robust workforce capable of sustaining growth and innovation in this vital sector.

Addressing labor skill shortages is not merely an operational concern; it is crucial for ensuring the long-term viability of the furniture industry as it adapts to changing market demands and consumer preferences. By fostering a culture of learning and adaptability, manufacturers can better navigate these challenges while continuing to deliver quality products that meet consumer needs.

FAQs

1. What are the main causes of labor skill shortages in the furniture industry?

Labor skill shortages in the furniture industry are primarily caused by an aging workforce, a lack of interest among younger generations in manufacturing careers, economic fluctuations, geographical disparities in job availability, and the need for workers to adapt to new technologies. These factors contribute to a significant gap between the demand for skilled labor and the available workforce.

2. How do labor skill shortages affect wages in the furniture manufacturing sector?

Labor skill shortages typically drive up wages in the furniture manufacturing sector as companies compete to attract and retain skilled workers. According to surveys, experienced staff such as upholsterers and cabinet makers are seeing wage increases due to their high demand and limited supply, reflecting the broader economic implications of workforce challenges in this industry.

3. What strategies can furniture manufacturers implement to address skill shortages?

Manufacturers can adopt several strategies to mitigate skill shortages, including investing in training and development programs, creating positive work environments with competitive compensation and career advancement opportunities, leveraging technology to enhance productivity, engaging with local communities to promote manufacturing careers, and advocating for favorable immigration policies to attract foreign talent.

4. What role does technology play in addressing labor skill shortages?

Technology plays a crucial role in addressing labor skill shortages by automating processes that reduce reliance on manual labor while enhancing overall productivity. Additionally, digital training platforms can provide easier access to skills development for current employees, helping them adapt to new tools and methodologies within the industry.

5. How significant is the impact of labor skill shortages on the overall economy?

The impact of labor skill shortages extends beyond individual businesses; it can hinder economic growth by limiting production capacity within the furniture industry and related sectors. A shortage of skilled workers can lead to increased production costs, delays in fulfilling orders, and reduced innovation, ultimately affecting consumer prices and market competitiveness.