The eco-conscious trend has significantly boosted the demand for bamboo, rattan, cane, and wicker furniture. These sustainable materials are not only elegant and durable but also environmentally friendly. However, like any natural product, they are susceptible to wear and tear, damages during transit, and aging. Refurbishing damaged goods made from these materials can be challenging, especially for manufacturers, retailers, and refurbishing professionals. In this blog, we’ll explore the key refurbishment challenges for bamboo, rattan, cane, and wicker furniture, along with actionable insights to overcome them.

1. Why Bamboo, Rattan, Cane, and Wicker Furniture Are Worth the Effort?

Before delving into refurbishment challenges, it’s essential to understand why these materials are so popular.

1.1. Eco-Friendliness and Sustainability

These materials are renewable, biodegradable, and leave a minimal carbon footprint, making them highly sought after in today's eco-conscious market.

1.2. Versatility in Design

From modern minimalism to vintage charm, bamboo, rattan, cane, and wicker are versatile materials used in furniture design.

1.3. Durability

While durable, improper handling or storage can lead to damages that require immediate attention.

2. Common Types of Damage in Bamboo, Rattan, Cane, and Wicker Furniture

2.1. Cracks and Splits

Natural fibers are prone to drying out over time, leading to cracks and splits in bamboo and cane.

2.2. Weaving Damage

Wicker and rattan furniture often suffer from broken or frayed weaving, especially when exposed to excessive weight or harsh environments.

2.3. Staining and Fading

Prolonged exposure to sunlight, moisture, or stains from spills can cause discoloration, which is challenging to restore.

2.4. Mold and Mildew

Humidity and poor ventilation can lead to mold and mildew growth, damaging the integrity and appearance of the furniture.

2.5. Structural Weakness

Loose joints, weakened frames, and compromised structural integrity are common issues in damaged furniture.

3. Refurbishment Challenges: The Toughest Hurdles

3.1. Identifying the Extent of Damage

One of the primary challenges in refurbishment is assessing the full extent of damage, especially for intricate wicker and rattan designs where internal issues may not be visible.

3.2. Sourcing Matching Materials

Finding the right replacement materials—whether it’s matching bamboo slats, cane weaving, or rattan poles—can be time-consuming and costly.

3.3. Preserving the Original Aesthetic

Refurbishing while maintaining the original look and feel of the furniture is a delicate balance. A poorly done repair can make the furniture look inconsistent or overly patched.

3.4. Specialized Skill Requirements

Repairing intricate wickerwork or weaving new cane seats requires skilled artisans. This labor-intensive process can be expensive and hard to find in certain regions.

3.5. Eco-Friendly Restoration Methods

While chemical-based solutions can be used to restore furniture, they may not align with the eco-conscious appeal of bamboo and rattan products.

3.6. Cost vs. Value Dilemma

For exporters and retailers, the cost of refurbishment often competes with the decision to discard or replace the item altogether, especially for low-margin products.

4. Strategies for Overcoming Refurbishment Challenges

4.1. Regular Maintenance to Minimize Damage

- Use natural oils like linseed or tung oil to prevent drying and cracking.

- Protect furniture from direct sunlight and excessive moisture to reduce the risk of fading and mildew.

4.2. Partnering with Local Artisans

Building a network of skilled artisans can ensure high-quality repairs for intricate wicker and rattan designs.

4.3. Investing in Material Inventory

Stocking commonly used materials like cane strips, rattan poles, and bamboo slats can save time when refurbishing damaged goods.

4.4. Eco-Friendly Repair Techniques

- Use water-based sealants and non-toxic adhesives to align with sustainability goals.

- Opt for natural cleaning solutions like vinegar or baking soda for mold removal.

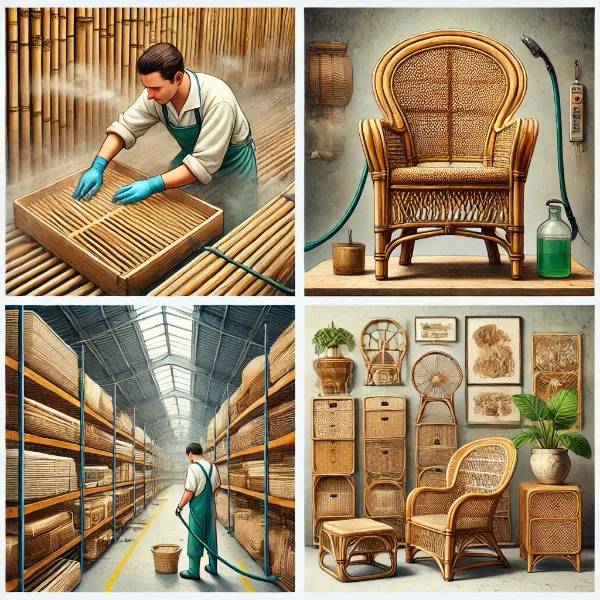

4.5. Advanced Tools and Techniques

Utilize tools like steamers to make bamboo pliable for repairs or specialized clamps to fix structural issues.

4.6. Outsourcing Refurbishment to Specialists

For large-scale operations, outsourcing repairs to dedicated refurbishment units can save time and ensure professional results.

5. Case Studies: Success Stories in Refurbishment

5.1. Bamboo Dining Set Restoration

A cracked bamboo dining set was successfully restored by replacing damaged slats and applying a fresh coat of eco-friendly varnish.

5.2. Rattan Chair Weaving Repair

An intricately woven rattan chair, damaged during transit, was repaired using matching rattan strands and traditional weaving techniques.

5.3. Wicker Sofa Refurbishment

A faded wicker sofa was revitalized with a fresh coat of weatherproof paint and structural reinforcement using natural adhesives.

6. Preventative Measures to Avoid Future Damages

6.1. Proper Packaging for Export

Use high-quality packaging materials like bubble wrap, corner protectors, and desiccants to prevent damage during shipping.

6.2. Climate-Controlled Storage

Store furniture in dry, well-ventilated areas to prevent mold growth and structural issues.

6.3. Customer Education

Educate buyers on how to maintain their furniture, including cleaning tips and ideal placement conditions.

6.4. Regular Inspections

Conduct routine checks to identify potential issues early and prevent extensive damage.

7. The Role of Technology in Refurbishment

7.1. Digital Tools for Damage Assessment

AI-powered inspection tools can help assess damage and estimate refurbishment costs accurately.

7.2. Online Marketplaces for Materials

Platforms like Alibaba and IndiaMart simplify sourcing replacement materials for refurbishment projects.

7.3. Virtual Training for Artisans

Offer virtual training programs to upskill artisans in advanced refurbishment techniques.

8. Refurbishment Challenges in Export Markets

8.1. Import Regulations and Standards

Exporters must ensure refurbished furniture meets import standards, which vary by country.

8.2. Transit Risks

Long transit durations increase the likelihood of damage, making quality packaging and insurance essential.

8.3. Consumer Perception

In some markets, refurbished goods are undervalued, necessitating transparent communication about the quality of repairs.

Conclusion

Refurbishing damaged bamboo, rattan, cane, and wicker furniture is undoubtedly challenging, but it also presents a significant opportunity for businesses to demonstrate their commitment to sustainability and craftsmanship. By addressing common refurbishment hurdles with innovative strategies, businesses can extend the lifecycle of these beautiful, eco-friendly products while maintaining profitability.

Whether you’re a manufacturer, exporter, or retailer, investing in effective refurbishment processes is a win-win. It not only reduces waste and boosts sustainability but also enhances customer satisfaction by offering beautifully restored, high-quality furniture.